Tools

Your tooling projects,

we treat them with precision!

DCM Précision is a company located in Burgundy-Franche-Comté and specialized for 30 years in the study, the realization of tools and the production of cut metal parts. According to your project, your requirements, we bring a global solution, recommended by our design office and conceived by our technicians, experts in tooling, cutting and finishing.

A complete service,

key to performance

Outillage, découpage sur presses traditionnelles et presses à coulisseaux multiples, tribofinition, parachèvement.

DCM Précision centralise toutes les phases du processus de fabrication sur un seul et même site. Nous nous adaptons à toutes les caractéristiques techniques des pièces métalliques que vous devez produire.

Study and understand your expectations

Upon receipt of your specifications, our design office analyzes and develops your project. Equipped with high-performance equipment, we are able to provide you with the solution best suited to your functional needs.

Design your tools

Trained in the latest industrial modeling software (CAD and CAM), our technicians develop the study and design of your tools according to your specifications. Our design office designs the tooling and then draws the detailed assembly drawings, intended for our mechanical workshop. At the same time, it carries out an FMECA research to prevent any risk of subsequent failure related to the tool.

Make your own tools

Once the study is completed, our technicians make the tooling in our mechanical workshop, which includes different sectors.

Several types of tooling can be designed to meet your needs and the complexity of the parts to be produced in the most appropriate way:

- tooling to follow,

- multiple slide tooling,

- Swiss" type tooling,

- rework tooling: This allows you to reduce raw material costs and to produce specific tools, while respecting your financial requirements).

At the end of this tooling design phase, our team puts your parts into production in our traditional press and multiple slide cutting workshops.

A workshop dedicated

to the manufacture of your tools

In our tooling workshop, divided into several sectors, a qualified team manufactures and develops the tools ordered.

Workshop

1 workshop with all conventional equipment(milling machine, lathe, pointing machine, drilling machines, etc.) for the assembly, adjustment and development of your tools

Electroerosion

1 wire EDM sector including :

- 3 FANUC wire machines

- 1 AGIES sinking machine

- 1 rapid drilling machine SODIK

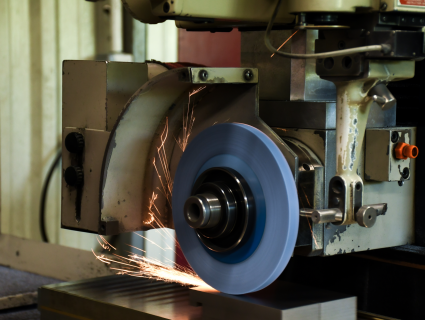

Rectification

1 rectification sector including :

- 6 surface grinding machines.

- 1 cylindrical grinding machine

Machining

1 numerical control machining sector including :

- 1 3-axis machining center C.N. MAZAK

- 1 C.N. MAZAK 4-axis turning center with bar feeder